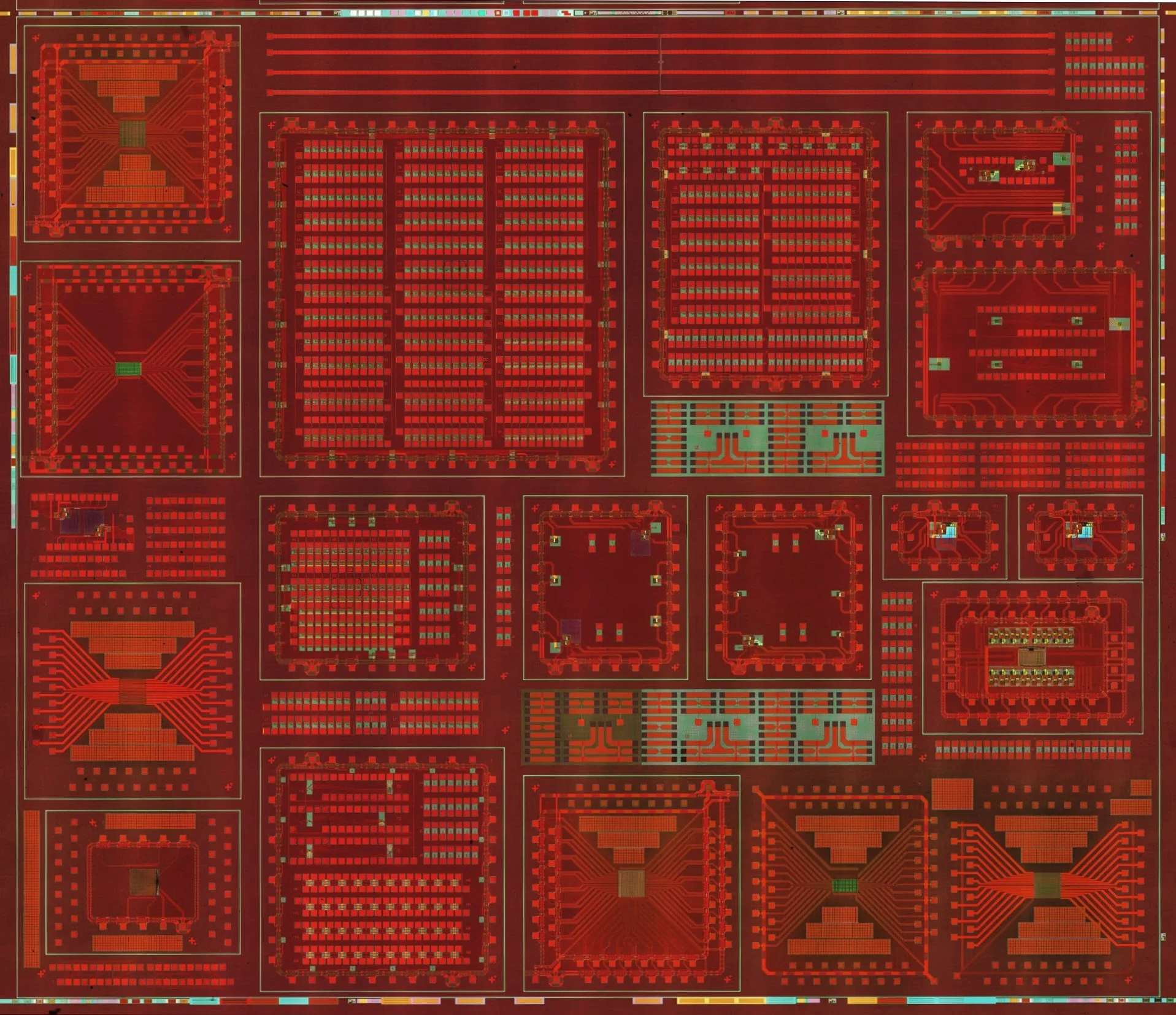

Prof. Mario Lanza’s team has developed industrial testing vehicles for memristive materials in diverse applications. The microchips contain front-end-of-line (FEOL) transistors and circuits to test multiple configurations, from a basic one-transistor-one-memrisor (1T1M) cell to 1 kilobit crossbar arrays with electrostatic discharge protection. The technology node used is 130 nm. Prof. Lanza’s collaborators can receive several samples for free. Click here for full description.

These microchips are special because they do not have passivation layer, so the memristive material can be easily integrated at the 4th metal layer. This cannot be done through a multi-project wafer (MPW) tape out, one needs to purchase an entire lot of wafers and this costs more than 150,000 USD. Moreover, most foundries around the world do not allow sharing this type of samples. However, Prof. Lanza works with a foundry that explicitly allows this type of collaborative research without the typical intellectual property and bureaucracy complications imposed by semiconductor foundries. Get your microchips easily, fast, and for free!

Most researchers explore memristive materials on unfunctional SiO2 wafers using large test structures and observe some degree of switching; however, later when they integrate that same material on the chip nothing works due to the different materials, device sizes, and thermal budgets. Then, they need to invest more time and resources to investigate why. Our microchips significantly increase the technology readiness level of your investigation.

Ask for free samples via email to: mlanza [at] nus [dot] edu [dot] sg